MANILDRA GROUPSTARCH DRYER 5

Industrial Project – Starch Dryer 5 – Bomaderry, NSW.

Client - Manildra Group

Project – Starch dryer 5

Cost – $1.2 Million

Duration – Approx 5 months, completed late 2016

Workforce – Total at peak of project – 22 personnel

Scope

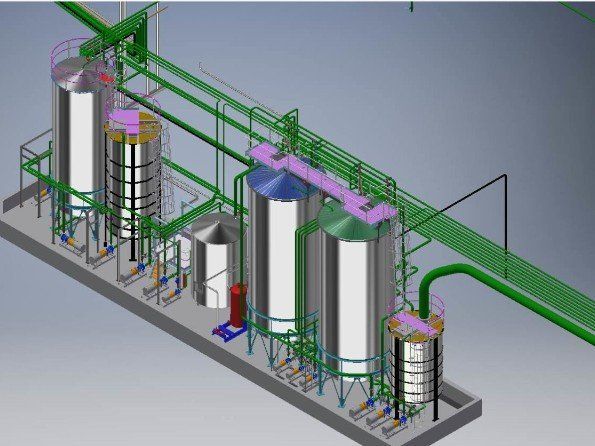

TRIPLENINE was contracted by The Manildra Group for the mechanical installation of new equipment piping to expand their starch drying capability at their Bomaderry site through the installation of a 20tph starch dryer (designated Starch Dryer 5). SD5 is a stand alone new building and will have wet product feed and a number of plant services supplied from the

existing starch production facility.

Systems include the following:

- RO Water supply;

- Primary wet starch supply from existing hydrocyclone feed tank;

- Secondary wet starch supply to/from existing reaction tanks 1 & 2;

- Clarified process effluent;

- Process effluent;

- Waste water;

- Steam supply;

- Steam condensate return; and

- Compressed air supply;

Construction challenges

Triplenine was proud to be apart of this project, this project proved to be a perfect fit for us and we were able to utilise our strength in 3D modelling and detailed design to allow us to pre-fabricate pipe bridge, pipe support, manifolds and piping spools in our workshop. Executing the project this way allowed us to still meet the desired practical completion date due to construction program delays.

Project stats

- 3.7km of ppiping ranging in size from 25mm to 450mm

- 380 flanges

- 3500 bolt sets

- A total of 2200 welds or 1.3km of welding

Due to the requirement for all stainless steel tubing to be Argon purged it was important for the client to define how we would control the quality of welding. QA was handled through our standard Quality Assurance Programs, quality plan and ITP’s and thrid party inspections. Triplenine successfully completed all piping with zero rejects.

Leadership in Safety

A key requirement of the project is to provide evidence of 10% of training per man hours accumulated throughout the project, TRIPLENINE has developed a plan to accommodate client requirements.