BEVERAGE PROJECT

Water processing & bottling plant

Nu-Pure Beverages, Sydney, NSW

Client - Nu=Pure Beverages

Project – Water processing & bottling plant

Cost – $2.6 Million

Duration – 8 months, completed Mid 2020

Workforce – Total at peak of project – 28 personnel

Scope

TRIPLENINE was contracted by Manildra Group to provide fabrication, installation and commissioning support of all process and services systems based on design specifications

Systems include the following:

- Unloading, unpacking and sorting of all equipment shipped from Italy/France, (Approximately 10 x 40’ shipping containers) required for the completion of the installation as detailed in the Piping and Instrumentation Diagrams.

- Installation of all vessels, valves, instruments, pumps, heat exchangers and other misc equipment

- Unloading, unpacking and sorting of piping shipped from Italy (approximately 10 x 40’ shipping containers).

- Fabrication and installation of all company supplied pipework. Piping will arrive generally as described in the piping isometric drawings and will require some site measurement and completion of fabrication of spools. Piping to be completed to ASME standards and insulated to client specifications

- Insulation of installed pipe work as called for by specification attached. Insulation was fully clad in 304 stainless steel.

Customer supplied equipment installation

Mechanical installation of owner supplied injection moulding, water process, utility support, and production equipment to support the installation of Krones blow molding/filling line

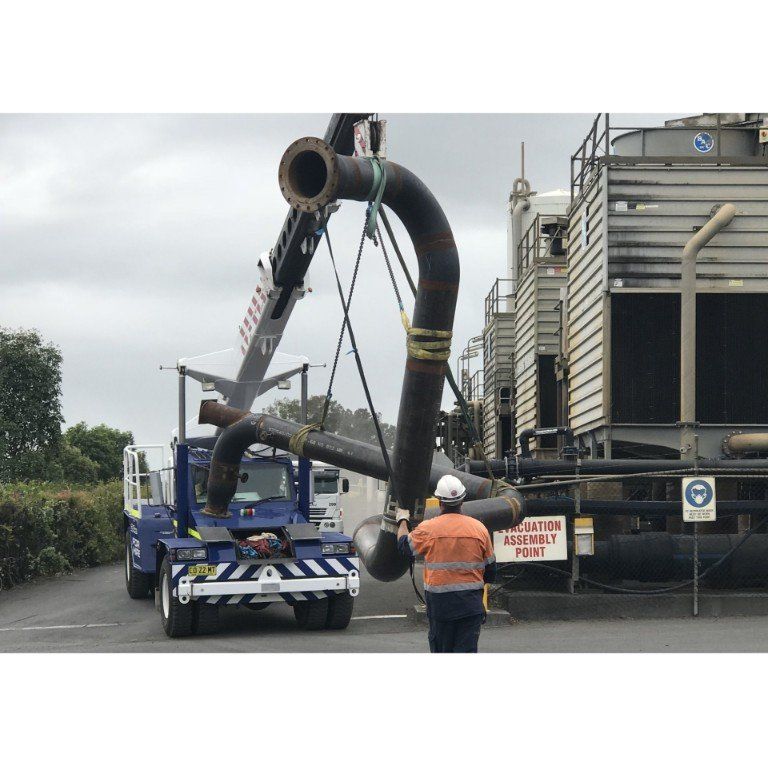

Vessel Installation

8 x large columns were installed, the largest being 42mts long and weighing 52T.

Site workshop

A dedicated fabrication area was established on site complete with office, storage area, floor protection and security for the extensive fabrication required.

Construction challenges

The new plant was located adjacent to the existing ethanol which presented a major risk due to the explosive environment, anything that could cause potential spark was prohibited from being used on the construction unless there were strict controls and monitoring in place to prevent potential sparking.

Triplenine work closely with the All Construction Engineering installation crew to install the piping simultaneously with the structural steel

For further information on this project contact Triplenine and one of our managers would be more than happy to help

CONTACT US

Leadership in Safety

Safety on our site is of utmost importance to us, ensuring everyone go home safely is our priority.