THE ENGINEERING OF TODAY

- By Ramzan R

- •

- 04 Apr, 2018

- •

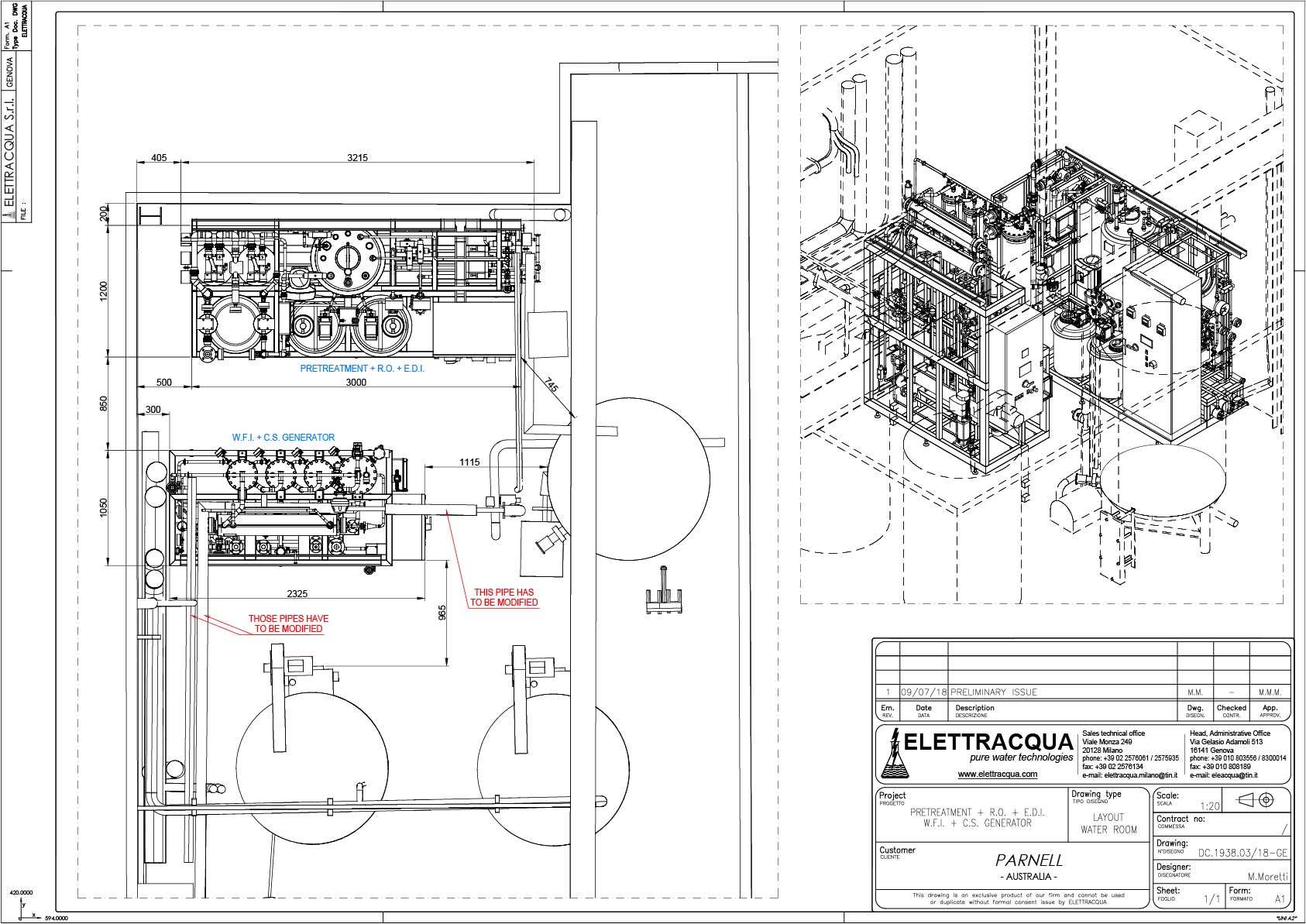

Sydney-based Archie Rose Distilling Co. has commenced construction of a new distillery and bond store in Botany NSW, scheduled for completion in mid-2019. Triple Nine Group are proud to announce that we have been engaged by Archie Rose Distillery for the mechanical install of the new distillery.

The new site, located just south of the brand’s existing Roseberry facility, will feature energy efficient brewing and distilling technology, some of which is the first of its kind in Australia. The distillery will be custom built to accommodate Archie Rose’s unique production processes, including its six-malt single malt mash bill, extensive use of specialty roasted malts, malted rye and individually distilled gin botanicals.

Archie Rose founder Will Edwards added, "this new site is an incredibly exciting step for us, not only will it allow us to increase our whisky production on custom designed equipment able to handle our unique mash bill and production processes, but it allows us to further consider sustainability across all aspects of our plant, equipment and processes, while continuing to support and champion boutique Australian farmers, maltsters and botanical producers"

Through word of mouth referrals Triple Nine Group were contacted by specialist Scotland based distillery designers, Allen Associates, and have worked closely with Allen Associates to provide advice on local design techniques, standards and supplier options for the project.

Triple Nine Group look forward to the projects progression and will keep you up to date over the coming months on this world class distillery for Australia.

Also included in the scope is the integration of the existing distribution system controls which will allow the complete system to be controlled from one point. Another unique offering from Triplenine Group which highlights our innovation and flexibility.

www. elettracqua.com

Stay tuned for further updates

Orbital Welding was first introduced in the late 1960’s as a way to reduce the weight of hydraulic and fuel systems on commercial aircraft.

In the Pharmaceutical Industry: In the late 1970’s orbital welding began to be used for Pharmaceutical water systems as a way to eliminate any Contamination or areas where water may be retained for possible bacteria Growth…as can happen with manual welding.

In the Semiconductor Industry: In the early 1980’s with the explosion in semiconductors orbital welding was introduced as a method to improve Yields through improved gas purity and leak integrity.